Counter-Rotating Extruder Twin Screw Barrel

Counter-rotating twin screw barrels can be categorized into conical-twin screw barrel and parallel-twin screw barrel.

About Counter-Rotating Extruder Twin Screw Barrel

A counter-rotating twin screw barrel is a key component in an extruder system, particularly used in the production of plastic products like pipes, profiles, and sheets. In a counter-rotating twin screw extruder, the two screws rotate in opposite directions. This counter-rotation creates a squeezing action between the screws, which is especially effective for processing materials with high viscosity or those that require gentle mixing.

The design of the counter-rotating screws are commonly used in the production of heat-sensitive materials and offers advantages in terms of output stability, better melt quality, and low energy consumption.

Counter-rotating twin screw barrels can be categorized into conical-twin screw barrel and parallel-twin screw barrel.

More than 25 years experience ensure the product quality

Qualified and experienced sales and engineering team

Twin Screw Barrel

A Conical-Twin Screw Barrel is mainly used for processing PVC products, such as PVC pipes, profiles, sheets, pellets and films. The unique and specific conical-twin screw geometry designs are offered to process PVC WPC SPC and foaming ingredients.

Applications of Conical-twin screw barrel

Both applications benefit from the conical-twin screw’s ability to handle high-output production, offering superior wear resistance and long service life, especially when processing high-fill PVC formulations or recycled materials.

Conical-twin screw barrel are favored for their durability, anti-wear, and anti-corrosion features, making them ideal for processing materials with fillers like wood fibers and stone powder that can wear down traditional machinery.

Conical-twin screw barrels are widely used in the production of PVC foam boards. Their design ensures uniform plasticization and stable material flow, which is crucial for achieving consistent foam density and surface smoothness.

How to choose geometry design of conical-twin screw barrel

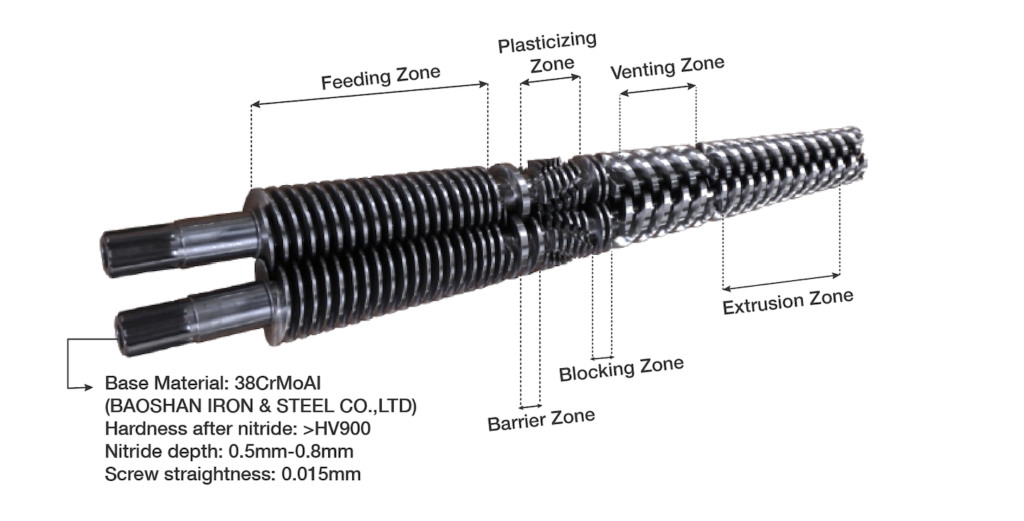

Conical-twin Screw geometry design is the most crucial point in PVC extruder processing. This is also our most significant technical “know how” during more than 25 years operational experience. As shown in the picture below, there’s feeding zone, barrier zone, plasticizing zone, venting and extruding zone of each conical-twin screw. The lead pitch and length of each zone are all determine the extrusion performance and PVC product quality.

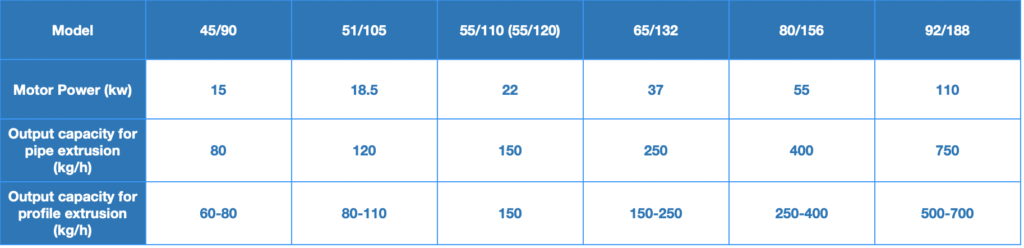

Models and Output Capacity of Conical-Twin Screw Barrel

Parallel-Twin Screw Barrel

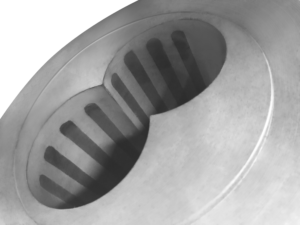

The screws in a counter-rotating parallel-twin screw barrel have a consistent diameter throughout their length. This design is beneficial for processes that require consistent shear and mixing over the length of the barrel. They are generally more robust and stable and can handle higher throughput rates compared to conical twins.

Conical-twin screw barrel VS Parallel- twin screw barrel

Both conical-twin screw barrels and parallel twin screw barrels are designed for use in twin screw extruders, but they differ in structure, application, and advantages. Each type of screw barrel has its unique strengths depending on the production requirements and material characteristics. Here’s a breakdown to compare them:

Conical: The screws with a larger diameter at the feed end and a smaller diameter at the discharge end. Parallel: The screws are cylindrical and run parallel to each other, with a uniform diameter from feed to discharge.

The conical shape provides higher compression, making it suitable for processing materials that require more intensive mixing and kneading. Offers consistent compression and uniform mixing, making it ideal for continuous processes.

Conical: PVC processing Extruding profiles and pipes, especially applications requiring high-pressure extrusion. Parallel: Higher-output applications requiring uniform processing

High Pressure & Compression; Good Feeding Performance; Compact design and less space required; Low screw speed provides better melting and mixing, minimizing shear stress on the material.

Can be used in a wide range of applications, including thermoplastics; High output and better heat transfer; Can be used in a wide range of applications, including thermoplastics.

Conical-Twin Screw Barrels are better for processing PVC in high-pressure applications or when space is a constraint; Parallel Twin Screw Barrels are ideal for large-scale production and when consistent, uniform material processing is required.

Bimetallic Solutions of Twin Screw Barrel

Nitride Screw Barrel

Mostly of JINZE screw barrel undergo a nitriding process to enhance its durability and performance. Nitriding is a basic heat treatment process in which nitrogen is diffused into the surface of the screw barrel to form hard nitrided layers. The hardness after nitride should be larger than HV900 and nitride depth should be 0.5mm-0.8mm

Bimetallic Screw Barrel

A bimetallic screw barrel is a type of extruder screw barrel that is welding coated by Nickel-based alloy mixed with a certain proportion of tungsten carbide. The primary purpose of this bimetallic structure is to enhance the performance and durability of the screw barrel, particularly in high-stress applications such as plastic extrusion.

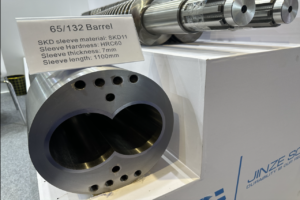

Barrel with SKD steel sleeves

A barrel with SKD steel sleeves is a highly durable extruder barrel designed to offer exceptional wear resistance, heat resistance, and strength. By using SKD steel, which is a high-quality tool steel, the sleeve provides a protective layer that significantly extends the service life of the barrel, especially in high-performance and high-throughput applications

25-Years Experience in Making Screw Barrel for Various Brands of Extruders