Plastic Extruder Screw Barrel Manufacturer, The Best Partner of Your Extrusion Process

High efficiency, Excellent melting and mixing screw geometry designs, Anti- wearing, Anti-corrosion bimetallic solutions help to save your extrusion cost.

THE SOLUTION

No matter what kind of screw barrel you are looking for, based on our extensive experience, we can manufacture it. The advantage of designing and manufacturing screw barrel,our aim is to save your production cost by improving the screw capacity and homogeneity.

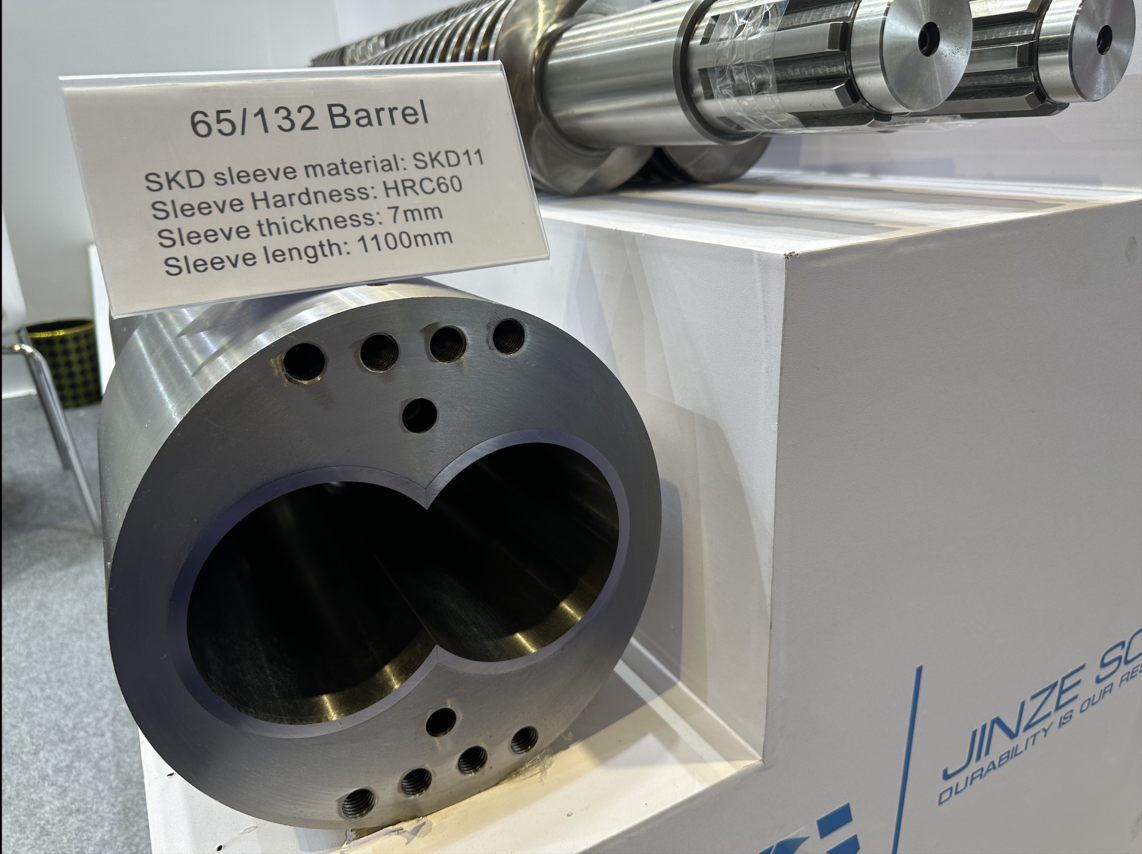

Twin screw barrel can be categorized into counter-rotating parallel-twin screw barrel and conical-twin screw barrel. Our expertise will help to improve your twin screw extrusion performance.

Optimize your extrusion process with JINZE SCREW's high-performance single screw barrels. Exceptional quality, customization, and longevity, making them ideal for various applications.

Enhance your production with JINZE SCREW’s top-tier injection moulding screw barrels. Our products are customizable, durable, and designed for high output and longevity.

Discover JINZE SCREW's bimetallic screw barrel solutions. With over 2,00 satisfied clients, our bimetallic screw barrels ensure long service life, and resistance to wear and corrosion. Ideal for various extrusion applications.

Maximize efficiency with JINZE SCREW’s high-performance screw extruders. Trusted by over 200 clients, our extruders are built for durability and high output. Perfect for diverse extrusion applications with superior quality and longevity.

Explore JINZE SCREW’s advanced compounding lines for PVC, PP, and PE. We provide high-quality, customizable solutions for efficient and reliable compounding processes. Enhance your production with our top-tier equipment.

Tour Our Workshop

Take a video tour through our workshop to see how screws and barrels are manufactured from raw steel material to heat treatment and final polish.

From raw steel material to a completed set of screw barrel, there are several working procedures. The normal production period of screw barrel is from 20-40 days.

What Sets Us Apart

Expertise

Facilities

Quality Control

Services

How To Work With Us

Reach out us via email , our website, or through social media channels. You can also visit our factory or attend trade shows where we exhibit.

Share the specifics of your requirements, such as the type of extruder screw barrel you need (e.g., conical-twin, parallel twin, single screw), material requirements, customization needs, and any specific performance targets (e.g., wear resistance, corrosion resistance).

Our team will guide you through product options, recommend the best solution for your application, and answer any technical questions you may have. We are also available to discuss your production capacities, delivery deadlines, and any particular challenges you face in the procurement process..

- Customized Quotation: Based on your specific requirements, we will provide a detailed quotation. This includes product pricing, lead time, customization costs (if applicable), payment terms, and shipping details.

- Clarification: We can discuss any concerns regarding the quotation. If you need any adjustments in the design or specifications, we will modify the offer accordingly.

- Technical Consultation: If your order requires a customized extruder screw barrel or bimetallic solutions, we work closely with you to define the exact design and performance requirements. This includes screw geometry, steel materials, and coatings.

- Design Approval: Once our engineers have prepared a design or modification plan, we will send you CAD drawings and technical details for approval before moving forward. We will ensure that the designs meet your performance and manufacturing standards.

Production Begins: Upon order confirmation, our production team starts the manufacturing process.

Quality Control: Each part undergoes strict quality control tests, including dimensional checks, material testing, hardness testing, and performance simulations. We ensure that each part meets the required specifications before moving forward.

Regular Updates: We provide regular updates on the production status, including photographs or videos of the work in progress and any pre-shipment inspections.

Packaging & Shipment: All products are carefully packaged to prevent damage during transport. We will arrange for the most efficient shipping method according to your needs.

After-Sale Service: Our relationship does not end at delivery. We provide comprehensive after-sale support, including troubleshooting, warranty service, and guidance on maintenance. If any issues arise, we will work with you to resolve them promptly.

Contact us to get the screw barrel installation manual now !

Frequently Asked Technical Questions

The steel material used for our extruder screw barrels is carefully selected to meet the specific requirements of your extrusion process, ensuring durability, performance, and resistance to wear. We offer several steel options based on the application and performance needs.

The most common steel we use for extruder screw barrel is 38CrMoAlA which the hardness after nitride is > HV900.

There are tutorial video of how to install twin screw barrel in our Youtube channel.

Yes, in addition to our high-quality screw barrels, JINZE SCREW also supplies a wide range of spare parts for plastic extruders to ensure the smooth and efficient operation of your extrusion systems.

We offer various components that complement our screw barrels, including: Heaters and cooling fans; Gearboxes; barrel adapters; feeders; electric parts of cabinet controller; etc

The lead time for a replacement screw barrel depends on several factors, including the complexity of the design, the material specifications, and the surface treatments required. Generally, our typical lead time for a replacement screw barrel is:

- Standard Screw Barrels: 4-6 weeks from order confirmation to shipment.

- Customized Screw Barrels: 4-8 weeks, depending on the complexity of the custom design and any additional surface treatments or coatings.

For urgent requests, we do offer expedited manufacturing options, but this may be subject to availability and additional fees. We highly recommend discussing your timeline with us in advance so we can accommodate your schedule and ensure timely delivery.

Yes, our screw barrels are fully customizable and designed to be compatible with a wide range of extruder brands.

If you have a specific brand or model in mind, feel free to share the details, and we’ll provide expert guidance on how we can meet your needs.

The surface treatment of an extruder screw barrel is crucial for enhancing its performance, durability, and resistance to wear, corrosion, and high temperatures. At JINZE SCREW, we offer a variety of advanced surface treatments to ensure the longevity and efficiency of our screw barrels in demanding industrial environments.

The main surface treatments we provide include: Bimetallic Coating; Nitriding;Chromium Plating (Hard Chrome Plating);Tungsten Carbide Coating

L/D ratio refers to the length-to-diameter ratio, which is the ratio of the screw's length (L) to its diameter (D). In an extruder, the L/D ratio is an important parameter as it affects the mixing, heating, and conveying of materials within the screw.

Yes, absolutely! At JINZE SCREW, we specialize in providing customized screw barrels to meet the unique processing requirements of our clients. We understand that different applications—whether it’s for specific materials, product types, or production conditions—demand precise customization.

Our engineering team works closely with you to design and manufacture screw barrels tailored to your exact needs. . We consider factors such as:Material Compatibility;Screw Geometry;Coatings & Surface Treatments;Specific Performance Requirements

We offer remote technical support to assist with installation, troubleshooting, and any operational issues you may encounter. Our experienced engineers are available to guide you through the process, provide setup advice, and answer any technical questions you may have to ensure a seamless installation.

On-Site Services:

In certain cases, we can arrange for on-site installation or troubleshooting services at an additional cost. This service is typically available for clients in strategic regions or when large-scale installations are involved. Please contact us directly to discuss your specific needs, and we can provide a tailored solution based on your location and project requirements.

At JINZE SCREW, we take pride in the quality and durability of our screw barrels. To ensure your investment is protected, we offer a comprehensive warranty on all of our products. Our standard warranty includes: Material and Manufacturing Defects;Performance Guarantee;Custom Solutions Support